MENU

CZ | CZK

CZ | CZK

No results found

Search Suggestions

Correct Settings for Liquid Types Simplify Automated Pipetting

Lab Academy

- Biotechnology

- Viscosity & Liquid Types

- Automation

- Liquid Handling Workstations

- Essay

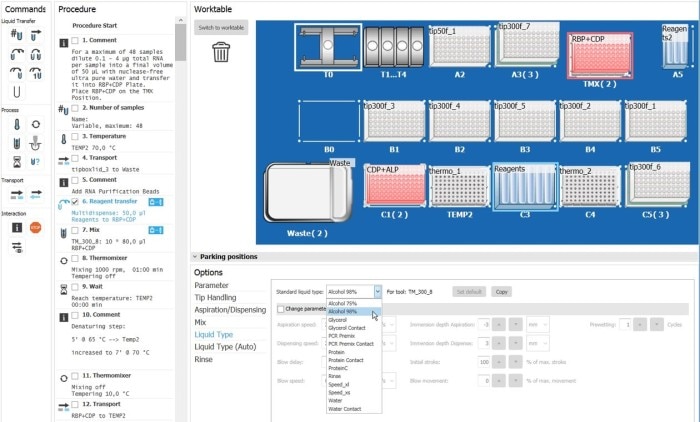

A well-designed automation software offers parameter settings for different liquid types. If the settings are not pre-programmed, it must be possible to individually set the parameters for optimal liquid aspiration and dispensing. Furthermore, for challenging liquids like cell culture medium or highly viscous solutions, additional options like “tip-dipping” or “mixing” should be selectable to simplify liquid transfer.

Challenging liquids such as viscous, volatile, infectious or protein-rich liquids can be transferred manually with the correct pipetting technique and tool. When using liquid handling robots and automation systems, the liquid type is usually not recognized automatically. The user must adjust distinct parameters for different liquid types to obtain accurate and precise pipetting results. Therefore, it is necessary to use a software that allows changing of those liquid handling related parameters. Ideally, optimized pre-settings for different liquid types, e.g. glycerol, alcohol 75 %, PCR premix, or protein should be entered in the software to simplify programming. Important parameters are the aspiration as well as dispensing speed. This regulates the movement of the piston in the dispensing tool. The speed can be stated in mm/s or µm/s. For viscous and volatile liquids, a slower speed is recommended than for aqueous solutions.

Another important option is the blow-out. A so-called blow delay is important to delay the blow-out and enable viscous liquids to flow down the tip completely. It is defined by the time in between the initial dispensing of the liquid and the final blow-out. When using pipette mode, the blow-out settings are of great importance when pipetting viscous liquids. When handling such liquids, accuracy and precision increase significantly with the correct blow delay and blow-out speed. When pipetting small volumes, the speed of the blow-out itself should be high. A high speed enables complete dispensing without drops clinging to the outside of the tip. Furthermore, pre-wetting in two or three cycles is essential for accurate transfer of volatile liquids. Ideally, the number of prewetting cycles is selectable in a reliable automation software. Another challenge is cell culture medium which tends to form foam due to the high protein content. Correct settings for this liquid type reduce or eliminate foam formation and increase pipetting accuracy and precision. Beyond that, cell culture medium drops easily attach to the outside of the pipette tip while aspirating or dispensing. A technique called “tip dipping” dips the tip into the liquid after the aspiration or dispensing to remove these drops on the outside of the tip. Using this feature, the correct sample volume is dispensed into the well or tube.

If no proper settings can be found after all for a liquid that is hardly expelled, the last option is a mix function. The liquid is then dispensed into the existing liquid and both liquids are mixed by up and down pipetting right in the tube or well. In this case, a well-designed automation software allows adjustment of mixing cycles, volume and speed. This mixing simplifies complete liquid dispensing and guarantees ideally stirred samples.

Another important option is the blow-out. A so-called blow delay is important to delay the blow-out and enable viscous liquids to flow down the tip completely. It is defined by the time in between the initial dispensing of the liquid and the final blow-out. When using pipette mode, the blow-out settings are of great importance when pipetting viscous liquids. When handling such liquids, accuracy and precision increase significantly with the correct blow delay and blow-out speed. When pipetting small volumes, the speed of the blow-out itself should be high. A high speed enables complete dispensing without drops clinging to the outside of the tip. Furthermore, pre-wetting in two or three cycles is essential for accurate transfer of volatile liquids. Ideally, the number of prewetting cycles is selectable in a reliable automation software. Another challenge is cell culture medium which tends to form foam due to the high protein content. Correct settings for this liquid type reduce or eliminate foam formation and increase pipetting accuracy and precision. Beyond that, cell culture medium drops easily attach to the outside of the pipette tip while aspirating or dispensing. A technique called “tip dipping” dips the tip into the liquid after the aspiration or dispensing to remove these drops on the outside of the tip. Using this feature, the correct sample volume is dispensed into the well or tube.

If no proper settings can be found after all for a liquid that is hardly expelled, the last option is a mix function. The liquid is then dispensed into the existing liquid and both liquids are mixed by up and down pipetting right in the tube or well. In this case, a well-designed automation software allows adjustment of mixing cycles, volume and speed. This mixing simplifies complete liquid dispensing and guarantees ideally stirred samples.

Read more

Read less